Construction of industrial flooring using epoxy coating

RELATED MATERIALS

DUROFLOOR-R Two-component, brushable epoxy coating

DUROFLOOR-PSF Two-component, solvent-free epoxy primer

DUROPRIMER Two-component epoxy primer

I. NATURE OF THE PROBLEM – REQUIREMENTS

Floors in factories, workshops, warehouses, garages, abattoirs, hospitals, etc. are constantly exposed to mechanical wear (e.g. friction, impact etc.) and chemical damage from thinned, inorganic and organic acids, alkalis, petroleum products, wastes etc.

Therefore, the final surface on such floors must have considerable mechanical and chemical strength as well as being easy to clean.

Industrial floors made from concrete, even those made with surface hardener and mechanical smoothing, but especially those from ordinary concrete or terrazzo, do not usually meet the above requirements (e.g. do not resist chemical damage from acids, get dusty etc.).

II. SOLUTION

The application of DUROFLOOR-R, brushable epoxy coating, on concrete floors, successfully meets requirements for moderate mechanical and chemical strength and provides a good aesthetic finish.

DUROFLOOR-R is a colored 2-component solvent-free epoxy system. Once it has hardened, it forms an easily cleaned final surface that displays great durability and strength against friction (abrasive resistance) as well as resistance to chemical effects, e.g. to thin organic and inorganic acids, alkalis, petroleum products, wastes, water, sea water etc.

However, where such floors are subject to heavy traffic (e.g. heavily loaded vehicles), or exposed to chemicals, the use of DUROFLOOR self-leveling epoxy flooring is recommended.

III. APPLICATION

Substrate preparation

- The surface on which the epoxy coating will be applied must be dry (<4% moisture) and stable, free of dust, loose particles, grease, etc and protected from underneath moisture attack.

- The surface must be properly prepared as appropriate, e.g. by grinding with a terrazzo machine, sand blasting, pellet blasting, etc., in order to open the pores to allow penetration of the primer and ensure better anchoring and bonding of the epoxy coating to the substrate.

- Subsequently, the surface should be carefully cleaned with a high suction vacuum cleaner.

- The properly prepared surface (as described above) is then primed with DUROFLOOR-PSF or DUROPRIMER epoxy primer.

Consumption of the primer: 200-300 g/m2.

On iron and steel surfaces, priming with EPOXYCOAT-AC, anticorrosive epoxy coating takes place in 2 layers. Second layer follows after the first one is completely dry, but within 24 hours.

Consumption of EPOXYCOAT-AC: 150-200 g/m2/layer.- Once the primer is dry, any imperfections in the surface (cracks, holes) should be filled and repaired with DUROFLOOR-R, mixed with grade 0-0,4 mm quartz sand (or Q35 sand), in the ratio of 1,5:1 to 1:2 by weight or using DUROFLOOR-PSF mixed with quartz sand, with a particle size of 0-0,4 mm (or Q35) in proportions of 1:2 up to 1:3 by weight.

- Application of DUROFLOOR-R brushable epoxy coating should take place after priming, but within 24 hours.

Application of DUROFLOOR-R

Mixing of DUROFLOOR-R components

Components A (resin) and B (hardener) are packaged in containers with predetermined mixing proportions. The whole quantity of component B should be added to component A and the mixture is stirred for approx. 5 minutes with a low-revolution (300 rpm) mixer. It is important that stirring reaches the wall and bottom of the container as well, in order to achieve uniform dispersion of the hardener.

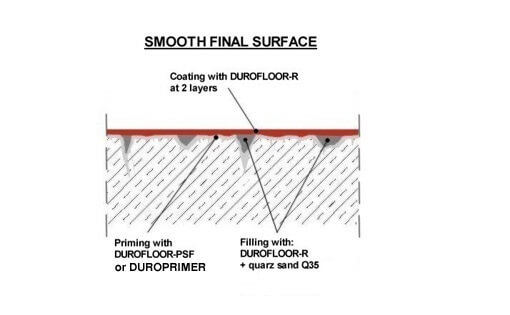

Creation of a smooth final surface

2 coats of DUROFLOOR-R are applied with a roller. The second coat should be applied once the first one has dried, but within 24 hours.

Consumption: 250-300 g/m2 per coat.

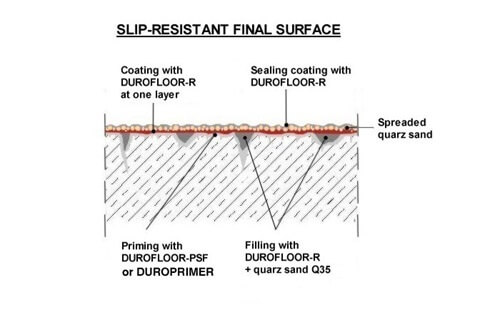

Creation of a slip-resistant final surface

- One coat of DUROFLOOR-R is applied with a roller.

DUROFLOOR-R consumption: 250-300 g/m2.- The still fresh coating should be sprinkled with grade 0,4-0,8 mm quartz sand, depending on the slip resistance required.

Quartz sand consumption: approx. 3 kg/m2.- Once the DUROFLOOR-R has hardened, any loose grains are removed with a high-suction vacuum cleaner.

- A single coat of DUROFLOOR-R is applied as a final sealing layer.

Consumption: 400-600 g/m2.

IV. REMARKS

- The quality of the concrete of the floor must be at least C20/25 (minimum cement content 350 kg/m3).

- In case that the substate is wet, its preparation should take place according to the technical solution PREPARATION OF FLOORS THAT ARE WET FOR THE APPLICATION OF EPOXY FLOORINGS”.

- Working time of epoxy systems decreases when ambient temperature rises.

- Bonding between successive layers may be severely affected by the intervention of moisture or dirt between them.

- Epoxy layers should be protected from moisture for 4-6 hours after application. Moisture may whiten the surface or/and make it sticky. It may also disturb hardening. Faded or sticky layers in parts of the surface should be removed by grinding or milling and laid again.

- In case that longer time than predicted interferes between the application of successive layers or in case that old floors are going to be laid again, the surface should be thoroughly cleaned and ground before application of the new layer.

- Before application, study the safety advice mentioned on the product’s labels.